TLDR

Tilt-up construction is one of the most popular building methods that involves casting concrete walls on-site, then tilting them into place.

As the construction industry evolves, innovations and advancements in materials and technology are also changing.

New materials with better durability and sustainability are being developed. Innovations such as 3D printing and robotics advancements are also contributing to greater levels of efficiency and precision.

On the other hand, design trends are also evolving; with curved panels and custom textures becoming the new normal.

The future of tilt-up construction faces challenges such as the need for skilled labor and increased competition. Still, it also presents opportunities for growth and innovation in sustainable building practices and new markets.

As such, the tilt-up construction industry must continue to innovate and adapt to meet changing demands and challenges.

The Future Of Tilt-Up Construction: Innovations And Advancements

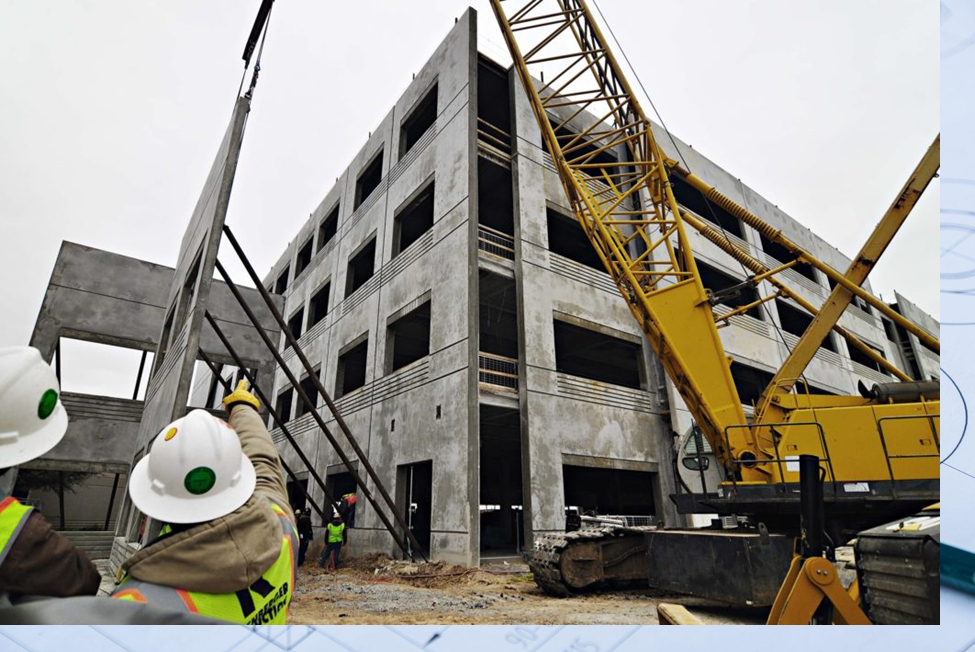

Are you familiar with tilt-up construction? It’s a method of building that involves casting concrete walls on a construction site, then lifting and tilting them into place. Tilt-up construction has been around for decades and is known for its durability, cost-effectiveness, and efficiency.

In this blog post, we’ll explore the future of tilt-up construction and the exciting innovations and advancements that are on the horizon.

Whether you’re a builder, an architect, or simply interested in the latest trends in construction, keep reading to discover what’s next for this building method.

Brief Overview of The Current State Of Tilt-Up Construction

Tilt-up construction is an efficient and cost-effective building method that is constantly evolving. It has been used for several decades in the construction industry. It involves casting concrete walls on site and then tilting them into place.

Tilt-up construction is known for its durability, cost-effectiveness, and efficiency, making it a popular choice for various building types, including commercial, industrial, educational, and healthcare facilities. Currently, tilt-up construction is used in various projects, ranging from small retail stores to large industrial warehouses.

It is popular in regions where the climate and soil conditions are receptive to this type of building. Growing demand for sustainable building practices and competition from other building methods characterize the current state of tilt-up construction.

Advancements In Materials

Advancements in materials are also driving changes in tilt-up construction. New materials are now being developed that offer increased durability, sustainability, and design flexibility. Here are some of the recent advancements in materials used in tilt-up construction:

Ultra-High-Performance Concrete (UHPC)

UHPC is a new type of concrete that is durable and stronger than traditional concrete. It allows for thinner and lighter panels, which can be easily lifted and tilted into place. Ultimately; increasing efficiency and reducing labor costs.

Insulated Concrete Forms (ICFs)

ICFs are prefabricated panels made from foam insulation used to create walls. They offer superior insulation properties and are highly energy-efficient, reducing heating and cooling costs.

Carbon Fiber Reinforced Polymer (CFRP)

CFRP is a lightweight and high-strength material increasingly used in tilt-up construction. It offers excellent resistance to weathering, seismic forces, and fire, making it an attractive choice for structures in areas prone to natural disasters.

Sustainable Materials

Sustainable materials such as recycled content, fly ash, and slag are increasingly used in tilt-up construction projects, reducing the carbon footprint of buildings and creating a more sustainable construction industry.

These advancements in materials are allowing for greater innovation and flexibility in the design and construction of tilt-up buildings. They are also helping to increase the sustainability and durability of these structures; making tilt-up construction an even more attractive option for builders and developers.

Technological Innovations

Technological innovations are transforming how tilt-up construction is carried out, making it more efficient, precise, and cost-effective. Here are some of the recent technological advancements in tilt-up construction.

3D Printing

3D printing is also being used in tilt-up construction to create molds for concrete panels. Overall it improves the precision and accuracy of the panels and reduces labor costs.

Building Information Modeling (BIM)

BIM is a digital representation of a building that includes detailed information about the design and construction of the building.

BIM software is used in tilt-up construction to improve collaboration between architects, engineers, and contractors. As a result, it reduces errors and improves the efficiency of the process.

Robotics

Robotics is used in tilt-up construction to automate the lifting and tilting of concrete panels. It helps in reducing the need for manual labor and ensures labor safety.

Augmented Reality (AR)

AR technology is used in tilt-up construction to visualize the building design and construction process in real-time. This allows architects, engineers, and contractors to identify potential problems and make changes before starting the construction.

These technological advancements are helping to increase the speed, efficiency, and safety of tilt-up construction projects while improving the final product’s accuracy and quality.

As technology advances, tilt-up construction will likely become even more efficient and cost-effective, making it an increasingly attractive option for builders and developers.

Design Trends

Design trends in tilt-up construction constantly evolve, offering new possibilities for building aesthetics and functionality. Here are some of the recent design trends in tilt-up construction:

Custom Textures

Tilt-up construction offers a range of textures, from smooth to texture. Custom textures are becoming popular as they offer unique and visually appealing finishes that can be customized to meet the specific needs of a project.

Curved Panels

Curved panels are emerging as a new trend in tilt-up construction. Panels can be curved using custom forms and casting techniques to create unique and visually appealing designs.

Integration of Glass and Metal

Integrating glass and metal elements into tilt-up construction is becoming increasingly common, adding visual interest and functionality to buildings. Glass panels can be used to create a modern and airy feel. In contrast, metal elements can add strength and durability.

Prefabricated Elements

Prefabricated elements, such as precast concrete columns and beams, are used in tilt-up construction to add visual interest and create unique and innovative building designs.

These design trends allow for greater creativity and flexibility in the design and construction of tilt-up buildings.

They are also helping to improve the aesthetics and functionality of these structures, making them more attractive to builders and developers. As design trends evolve, tilt-up construction will likely remain popular for years.

Sustainable Practices

Sustainability is becoming an increasingly important consideration in tilt-up construction, with builders and developers seeking to minimize the environmental impact of their projects. Here are some of the sustainable practices that are being used in tilt-up construction:

Energy Efficiency

Energy-efficient design is a key consideration in tilt-up construction. Building orientation, insulation, glazing, and lighting are all factors that can significantly impact a building’s energy consumption.

Use of Recycled Materials

Using recycled materials in tilt-up construction, such as recycled concrete, can significantly reduce the environmental impact of the building.

Water Conservation

Water conservation is becoming increasingly important in tilt-up construction. Practices such as rainwater harvesting, low-flow plumbing fixtures, and water-efficient landscaping can significantly reduce a building’s water consumption.

Use of Renewable Energy

The use of renewable energy, such as solar and wind power, is becoming more common in tilt-up construction. Solar panels can be incorporated into the design of the building to provide clean and renewable energy.

Sustainable Site Development

Sustainable site development practices, such as using native plants, reducing impervious surfaces, and preserving natural features, can help to minimize the impact of the building on the environment.

By implementing these sustainable practices, tilt-up construction can help minimize building construction’s environmental impact and promote a more sustainable future. As sustainability continues to be a growing concern, these practices will likely become even more important in tilt-up construction projects.

Challenges And Opportunities

Tilt-up construction offers numerous advantages, such as better speed of construction, cost-effectiveness, and higher durability.

But like any construction method, it presents certain challenges and opportunities. Here are some of the key challenges and opportunities associated with tilt-up construction:

Challenges:

- Site Constraints: Tilt-up construction requires a large, flat site, which can be challenging in urban areas with limited space.

- Labor Costs: Tilt-up construction requires skilled labor, which can be expensive and difficult to find in certain areas.

- Transportation and Logistics: Transporting and lifting large concrete panels can be a logistical challenge, requiring specialized equipment and expertise.

- Design Limitations: Tilt-up construction can be limited in design flexibility, especially compared to other construction methods such as steel or wood framing.

Opportunities:

- Speed of Construction: Tilt-up construction is faster than traditional construction methods, allowing for faster occupancy and return on investment.

- Cost Savings: Tilt-up construction is generally less expensive than other construction methods, making it an attractive option for developers and builders.

- Durability: Tilt-up construction provides long-lasting and durable structures with low maintenance requirements.

- Design Possibilities: While there are limitations to the design flexibility of tilt-up construction, it also offers unique design possibilities, such as custom textures, curved panels, and the integration of glass and metal.

By understanding and addressing the challenges and opportunities associated with tilt-up construction, builders, and developers can effectively leverage this method to create high-quality, cost-effective, and durable buildings.