Assurance of Quality

Every product is made to the highest standards of durability and workmanship, thanks to our unwavering dedication to quality.

At Custom Rock, we turn ordinary concrete structures into extraordinary works of art. We provide architects, engineers, contractors, and designers with concrete form liners with distinctive patterns and textures.

From enhancing the aesthetics of buildings to creating visually striking landscapes, our concrete form liners are the perfect solution for adding depth and character to any environment.

Concrete form liners are more than just functional components of construction. They are tools for creative expression. Form liners may turn boring buildings into eye-catching masterpieces by introducing complex patterns and shapes into the concrete surface.

At Custom Rock, we produce and design a wide range of concrete form liners to bring your vision to life.

Concrete patterns and textures play a crucial role in defining the aesthetic. Whether you want a clean, contemporary design or a rustic, natural appearance, our concrete form liners will help you get the desired result. With options ranging from textured stone to intricate wood grain, you have the freedom to choose the perfect pattern to complement your project's style and ambiance.

Concrete forms serve as the foundation for creating concrete structures of various shapes and sizes. Concrete forms serve as the framework for pouring and molding concrete into the desired shape for structures such as walls, columns, bridges, and facades.

At Custom Rock, we offer a diverse selection of form liners to work in tandem with concrete forms, including standard panels and custom molds, to accommodate a wide range of construction needs.

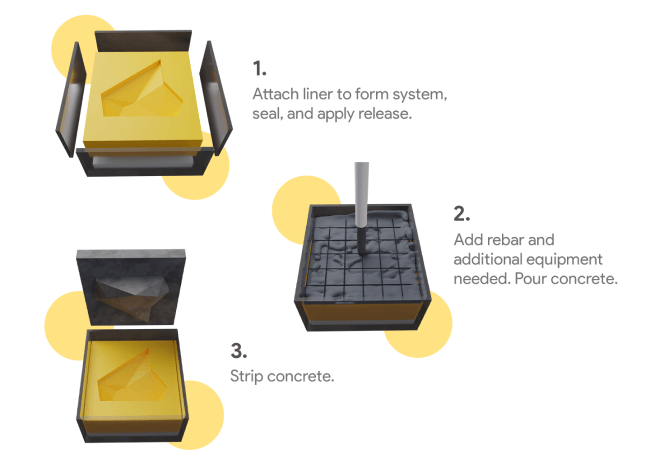

Understanding the Basics

Form liners are the secret behind achieving intricate textures and patterns on concrete surfaces. These rubber or plastic molds are used to line the inside of form systems, and imprint desired designs onto newly poured concrete.

Once set, the forms are stripped away, revealing the beautifully textured surface underneath.

Plastic Or Urethane Form liner For My Project?

Our concrete form liners are available in two materials: Plastic and Urethane. Each has its own purpose. Plastic and Urethane. Learn more about single-use and multi-use formliners.

At Custom Rock, we understand that every project comes with its own set of requirements and challenges. For this reason, we provide form liners in two remarkable materials, each designed to meet unique requirements and preferences.

Ideal for projects with low to medium reuse requirements, plastic form liners offer a perfect balance of affordability and practicality. These adaptable liners are simple to work with and install, which makes them a great option for situations where efficiency and cost-effectiveness are crucial.

Despite their affordability, plastic form liners do not compromise on quality, ensuring consistent and reliable results with every use.

For projects that demand unparalleled precision and durability, our urethane form liners are the ultimate choice. These form liners, which are made of premium materials and have outstanding durability and pattern resolution, are perfect for applications that call for fine detail and repeated usage.

Whether you are working on intricate architectural designs or large-scale infrastructure projects, urethane form liners deliver unmatched performance and longevity, ensuring that your concrete surfaces stand the test of time.

Plastic is an affordable alternative to achieve an architectural concrete finish. It is mainly used when a small number of pours are needed or when you are pouring large areas at one time.

Urethane is used for large projects or when high detail and high relief of the concrete pattern are needed. Urethane is best for large projects that can take advantage of the multiple reuses making these liners the most cost effective option. Learn More

Transforming Concrete in Every Construction Method

Custom Rock form liners are versatile and an essential elements in a wide array of construction methods. Our form liners contribute significantly to the improvement of concrete aesthetics in a variety of applications, from the adaptability of cast in place to the effectiveness of precast and the speed of tilt-up.

Concrete Form liners are used by contractors in three different ways.

No two projects are alike, which is why we pride ourselves on offering custom solutions tailored to your specific requirements. Whether you are working on a public infrastructure project, commercial building, or residential construction, our team of professionals will collaborate directly with you to design and produce concrete form liners that precisely match your requirements.

With our state-of-the-art technology and craftsmanship, we can create intricate patterns and textures that elevate the overall look and feel of your project.

At Custom Rock, quality is our top priority. Our concrete form liners are made to the highest standards of performance and durability using only the best components and production techniques.

When you partner with Custom Rock, you gain access to a wealth of benefits that set us apart from the competition:

Assurance of Quality

Every product is made to the highest standards of durability and workmanship, thanks to our unwavering dedication to quality.

Innovation

We stay at the forefront of industry trends and technologies, constantly evolving to deliver cutting-edge solutions to our clients.

Versatility

Our products may be used in a variety of contexts, including infrastructure projects, residential and commercial buildings, and more.

Sustainability

We use eco-friendly products and production techniques that minimize waste and lower our carbon footprint because we place a high priority on environmental stewardship.

Architects, Engineers, and Designers use Custom Rock form liners for commercial and residential buildings, schools, Industrial buildings, stadiums, theme parks, infrastructure work, public art, and signs. DOTs use Custom Rock form liners for infrastructure work (subways, roads/highways), public art, and signs.

Formliners are flexible or rigid molds that are placed inside formwork or molds to create textured or patterned surfaces on concrete. They are typically made of materials such as rubber, plastic, or foam. Formliners are used to add visual interest and texture to concrete walls, columns, beams, and other architectural elements. They offer a cost-effective and efficient way to achieve decorative finishes in both new construction and renovation projects.

At Custom Rock, we offer a wide range of textures and patterns for formliners to suit various design preferences. Our selection includes options like stone, brick, wood, tile, and custom designs. Whether you're looking to replicate the appearance of natural materials or create a unique concrete pattern, we can provide formliners that meet your specific project requirements.

Yes, formliners can be used for both interior and exterior applications. They are commonly used in a variety of settings, including commercial buildings, residential projects, public spaces, and more. Formliners allow you to add visual interest and texture to both interior and exterior concrete surfaces, enhancing the overall aesthetics of your project.

Formliners are installed by placing them inside the formwork or molds before pouring concrete. The formliners are securely attached to the formwork to ensure they stay in place during the concrete pouring process. After the concrete sets, the formwork is removed, revealing the textured or patterned surface created by the formliners.

In many cases, formliners can be reused multiple times, depending on

their material and condition. Flexible formliners, such as those made of

urethane, are generally more durable and can withstand multiple uses.

Rigid formliners, such as those made from plastic or foam, have a

shorter lifespan. Certain plastic liners like ABS material, can be reused

for several pours if properly maintained and handled.

When using formliners, it's important to consider factors such as the complexity of the design, the desired texture or pattern, and the type of concrete being used. Some intricate or detailed patterns may require additional care during the installation process. It's recommended to consult with our experts or a professional contractor to ensure proper installation techniques and to address any specific considerations for your project.

Concrete form liners are molds crafted from materials like plastic or urethane, which are inserted into formwork before pouring concrete. By adding visual appeal and architectural complexity to concrete surfaces, they produce beautiful patterns and textures that turn buildings into engaging pieces of art.

Yes, custom concrete patterns can be achieved with form liners. Manufacturers often provide customization options, allowing for the creation of unique designs, logos, or patterns tailored to specific project requirements.

There are various types of concrete forms, including plywood forms, steel forms, plastic forms, and fabric forms. Each type serves specific purposes, ranging from creating smooth surfaces to withstand heavy loads in large-scale projects.

Of course! With the many customization possibilities we provide at Custom Rock, you may design distinctive patterns and textures that are suited to the requirements and style preferences of your project.

Our staff can help you realize your idea, whether you have a specific design in mind or need help developing one.

Our concrete form liners are available in two primary materials: plastic and urethane. Because they are inexpensive and simple to handle, plastic liners are an excellent choice for applications with low to medium reuse requirements.

Urethane liners, on the other hand, are perfect for high-impact applications and projects with exacting quality requirements because of their exceptional detail and durability.

The lifespan of concrete form liners varies depending on several factors, including material quality, frequency of use, and proper maintenance. Our form liners are often made to last several uses, offering reliable performance and value over time.

Yes, sustainability is a core focus at Custom Rock. We use environmentally friendly materials and production techniques to minimize waste and lessen our impact on the environment while creating our concrete form liners.

By selecting our form liners, you can support environmentally friendly building methods without sacrificing performance or style.

Absolutely! Our form liners are designed to endure a variety of weather circumstances, including chilly climes. Regardless of the climate, they guarantee constant performance and longevity by retaining their structural integrity and functionality even in extremely high temperatures.

Whether you are embarking on a new construction project or renovating an existing structure, Custom Rock is here to turn your concrete vision into reality. We are certain that we can surpass your expectations and improve the visual attractiveness of your next project with our unmatched experience, first-rate goods, and unshakable dedication to client happiness.

Contact us today to learn more about our concrete form liners, patterns, and forms and discover the endless possibilities of concrete design.