TL, DR

Skyscrapers are crucial in developing creative and efficient building designs that complement the city and its people. This article highlights trends and innovations that characterize the growing developments of new skyscraper designs.

As the consequences of climate change intensify, the construction industry is paying attention to its environmental impact and exploring methods to mitigate it.

One such approach is the development of skyscrapers equipped with energy-efficient air conditioning systems, double facades, and solar PV systems. These features are intended to minimize energy consumption, resulting in long-term cost savings.

This trend toward environmentally conscious construction is largely driven by the necessity for the construction industry to lessen its impact on the environment due to the growing urgency for environmental conservation.

Another trend is the use of intelligent technologies in the construction of skylines. These technologies can help to optimize energy efficiency and reduce waste.

IoT and AI-based smart skyscrapers use smart and connected technologies to control, monitor, and modify the elements that make up the built environment, enhancing users’ comfort and increasing energy efficiency.

Mixed approaches are taken due to rapidly increasing population densities in urban landscapes, where there is an increasing need for integrated high-rise buildings. These structures feature living, working, shopping, and production floors under one roof.

With time, the idea of vertical urbanism is emerging, and with that, people are changing the traditional view on constructing tall constructions. Architects are now managing to incorporate nature into buildings instead of heaping the floors on top of each other.

There is a concept known as adaptive reuse, which means that instead of destroying the entire skyscrapers to construct new ones fresh, the structures are retrofitted for other uses.

This approach is cost-effective and environmentally friendly as it involves less use of new materials and avoids excessive wastage and negative impact on our cities’ heritage. Innovative construction methods are also affecting the future of skyscrapers.

Pre-fabrication, where structures are constructed from matching segments, is rising since this technique is faster and more economical.

The Future of Skyscrapers: Trends and Innovation

Throughout history, skyscrapers have symbolized ambition, technological progress, and economic prosperity. Urban areas experience a rise in the number of skyscrapers due to several factors. These include population growth in cities, limited land availability, and the aspiration to create distinctive city skylines.

This article highlights trends and innovations that characterize the growing developments of new skyscraper designs.

Trends and Innovations in Skyscrapers

Let’s take a look at some trends and innovations regarding skyscrapers in this section:

1. Sustainable Design and Construction

High-rise buildings, which used more energy than needed in the past, are now being constructed with sustainable design in mind. To adopt sustainability, architects and now inclined towards approaches such as Green Building materials, energy Conservation measures, and sustainable construction methods.

Modern construction materials like cross-laminated timber (CLT), recycled steel, sustainable concrete, etc., achieve sustainable designs. For instance, CLT helps reduce greenhouse gas emissions and provides optimum support to structures with tall heights and heavy loads.

On the same note, new skyscrapers with efficient air conditioning, double facades, and solar PV systems are being built. These features consume less energy and cut down costs in the long run.

2. Smart Skyscrapers

Another emerging trend is the application of intelligent technologies in constructing skylines. IoT and AI-based smart skyscrapers use smart and connected technologies to control, monitor, and modify the elements that make up the built environment. This enhances the users’ comfort and increases energy efficiency.

For example, IoT sensors can be used to sample air quality, water usage, and other parameters and supply real-time data to adjust different systems. AI can also forecast when a specific equipment is likely to require maintenance, thus preventing the development of problems that may be difficult to handle.

In addition, it also contains features such as intelligent elevators and escalators that may change their operations according to the movement of people within a building. This way, they only consume energy when people are moving in large numbers at some particular places on the premises. Furthermore, the building incorporates advanced features like intelligent elevators and escalators.

These systems have the ability to adjust their operations based on the movement patterns of individuals within the building. Consequently, energy consumption is optimized as these systems only activate when significant foot traffic is detected in specific areas of the premises.

3. Mixed-Use Developments

Mixed approaches are taken due to rapidly increasing population densities in urban landscapes, with an increasing need for integrated high-rise buildings. These structures feature living, working, shopping, and production floors under one roof. This trend is mainly rooted in developing more semi-autonomous neighborhoods within cities to cut on long daily journeys and save time for residents.

Due to rapidly increasing population densities in urban areas, cities are adopting mixed-use approaches by constructing integrated high-rise buildings. These structures combine living, working, shopping, and production spaces within a single building. This trend is driven by the desire to create more semi-autonomous neighborhoods, reducing long daily commutes and saving time for residents.

Multi-function tall buildings have several advantages, including efficiency in using the limited land available and versatility. They also contribute to forming active urban societies since a wide range of services and facilities, such as health clubs, eating places, businesses, and amenities, are usually within distance of each other.

4. Vertical Urbanism and Green Spaces

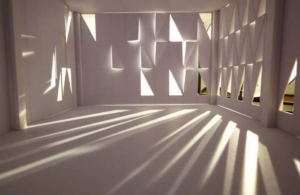

With time, the idea of vertical urbanism is emerging, and with that, people are changing the traditional view on constructing tall constructions. Architects are now incorporating nature into buildings instead of heaping the floors on top of each other.

This involves adapting the edifice to the environment by including green roofs, roofs, vertical gardens, and crop growers. Vegetation in buildings has multiple advantages, such as positively impacting the air quality of the interiors, supporting the growth of a biodiverse population, and boosting the well-being of the employees.

Vertical gardens provide shade and cut down on heating to eliminate the demand for air conditioning, and green roofs help absorb rainwater, thus eliminating the chances of flooding. Such features also serve the purpose of increasing building sustainability while at the same time promoting health among the people living and working in such buildings.

5. Adaptive Reuse and Resilience

With the growth of cities come the changes in their structures and forms of construction. There is a concept known as adaptive reuse, which means that instead of destroying the entire skyscrapers to construct new ones fresh, the structures are retrofitted for other uses.

This approach is cost-effective and environmentally friendly as it involves less use of new materials and avoids excessive wastage and negative impact on our cities’ heritage. For example, there are some cases where old office structures are being converted into residences or some other form of use, giving new functions to old ones.

Due to climate change’s effects, it is essential to design buildings that can cope with these events. This includes structural enhancements, flood protection, and even earthquake protection technologies.

6. Innovative Construction Techniques

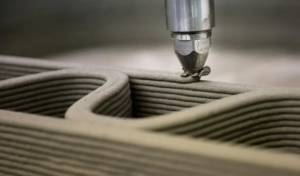

Innovative construction methods are also affecting the future of skyscrapers. Pre-fabrication, where structures are constructed from matching segments, is on the rise since this technique is faster and more economical. By using this method, architects minimize construction time, reduce material requirements, and ensure better quality.

In addition, the use of drones and robotics in construction projects is also getting its hype. A drone can be used for aerial photography for a location for legal purposes, construction progress inspection, and even the delivery of construction materials.

On the other hand, robots are also capable of performing repetitive and hazardous operations which can reduce labor costs. These include aspects such as laying bricks or welding, which in turn also minimizes the possibility of work-related injuries on sites.

With development ever speeding up and changing the face of cities constantly, tall buildings will remain an irreplaceable part of the urban world. It is the answer to many of the problems that face in terms of living today.